Meet us at K Show 2025

Booth No: Hall 12, C01-13

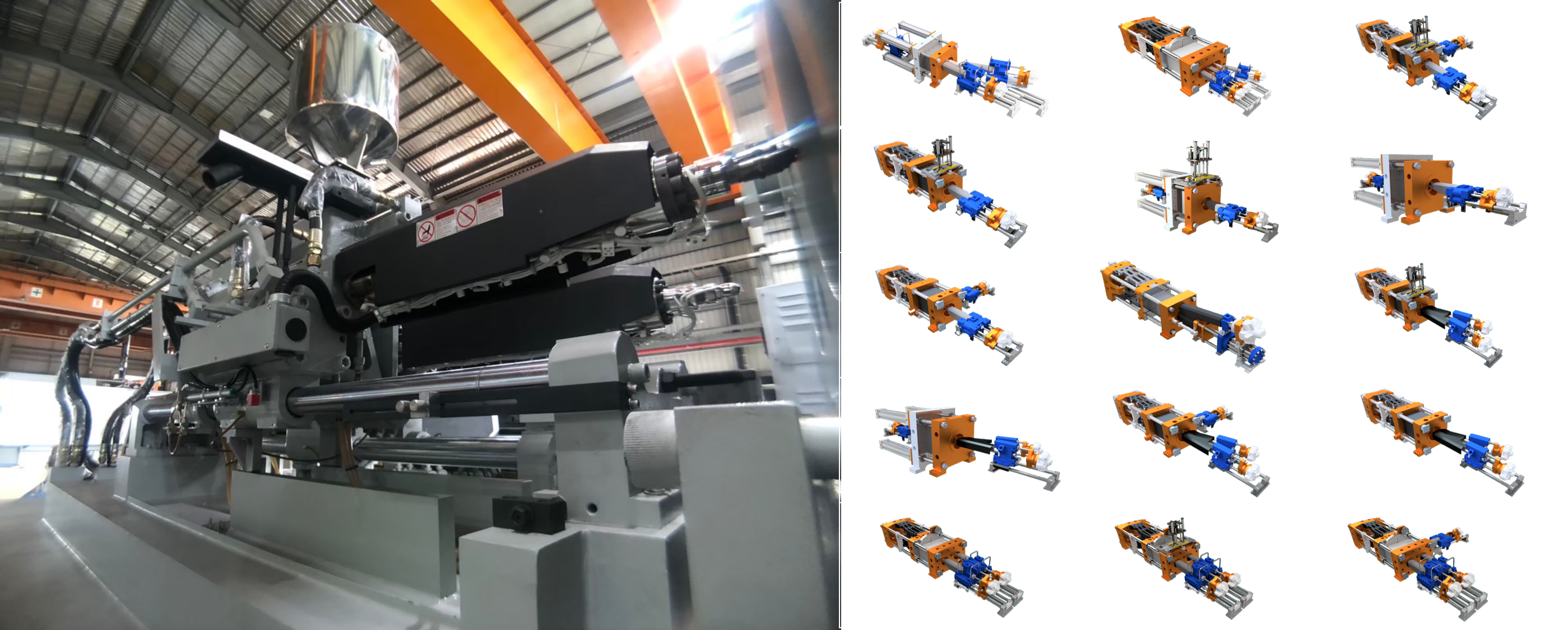

Two-Shot Injection Molding Machine is an advanced manufacturing solution designed to produce multi-material or multi-color parts in a single molding cycle. Also known as two-shot or multi-shot injection molding, this technology allows for injecting two or more different materials and colors into a single mold, creating complex and high-quality parts with distinct properties or aesthetics. Depending on the requirement, this machine can be customized for up to three or four shots.

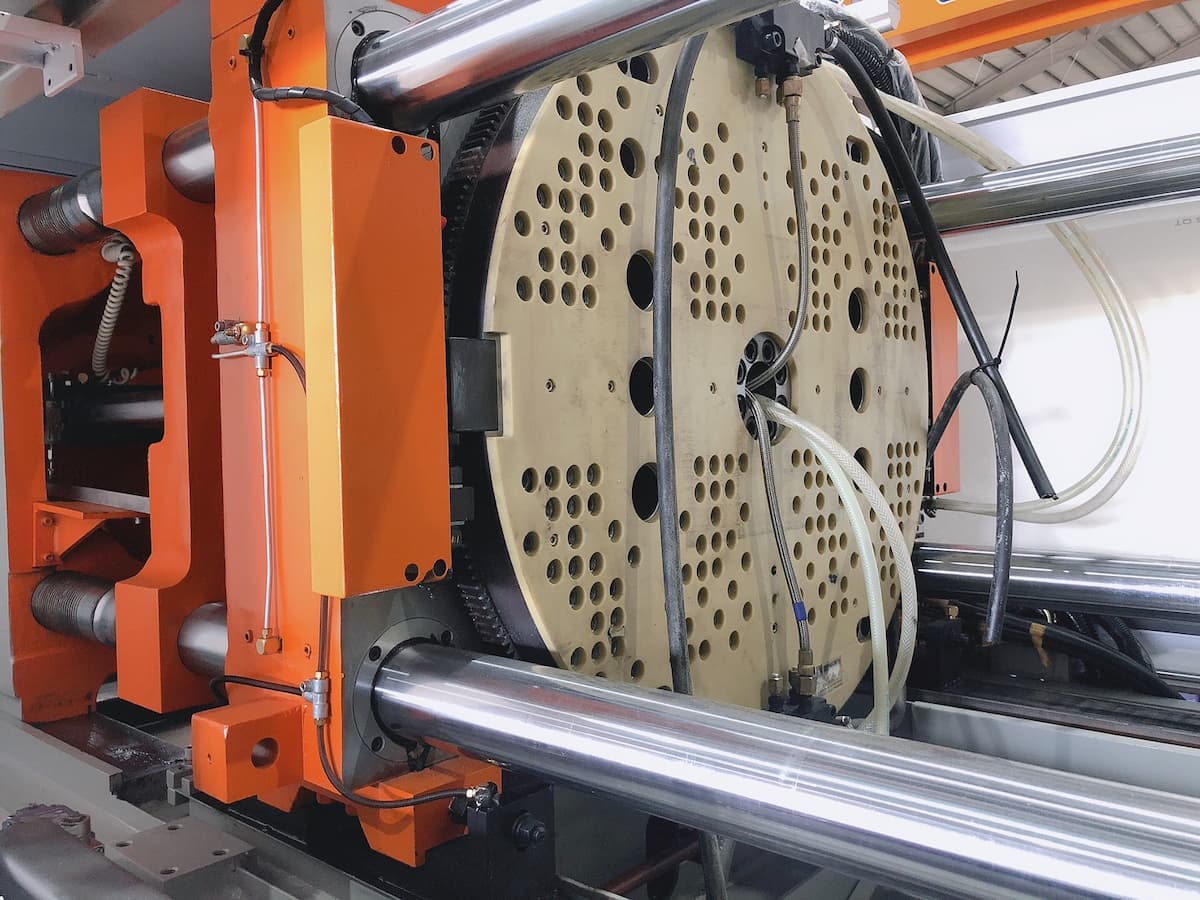

Two-shot injection molding machines are highly versatile and are used across various industries. They are ideal for applications requiring components with different material properties. We focus on the machine's performance and dedicate designs to rotating tables with triple safety from mechanism, electric, and hydraulic for accurate positioning and leanness.

Patent Design Detail: https://www.huarong.com.tw/page/product/en/injection-molding-machine/multi-injection/detail/hdc-co-injection/

Here are some key applications of the Dual-Shot Injection Molding Machine:

Automotive Industry:

Consumer Electronics:

Medical Devices:

Consumer Goods:

Packaging:

Electrical Components:

Sporting Goods:

Machine Detail: https://www.huarong.com.tw/page/product/en/injection-molding-machine/multi-injection/detail/hdc-co-injection/

| Product Description | The HDC Series Two-Shot Injection Molding Machine from Huarong offers an advanced and efficient solution for producing multi-material or multi-color plastic parts in just one molding cycle. Engineered for high flexibility, this machine can integrate two or more different materials or colors into a single mold—and is customizable for up to three or four shots—delivering exquisite finishes with complex functional designs, all without requiring secondary processing steps. Built for precision and safety, the HDC Series features a patented rotary-table system equipped with triple safety measures (mechanical, electric, hydraulic) to ensure accurate positioning and lean operation. |

| Features | ◆ One-Cycle, Multi-Material Molding - Produces complex, multi-color or multi-material parts in a single injection cycle—no secondary assembly required. ◆ Up to Four Shots Customization - Flexible configuration allows the use of two, three, or even four material/color shots per mold according to production needs. ◆ Patented Rotary-Table Safety System - Ensures precise mold alignment and is safeguarded by mechanical, electrical, and hydraulic protection. ◆ Cleaner Aesthetics & Enhanced Bonding - Enables strong molecular bonding between materials, resulting in durable, seamless parts with improved visual appeal and handling comfort. ◆ Efficiency & Cost Savings - Reduces manufacturing steps and labor by consolidating multiple materials into one process, lowering production time and costs. |

|

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.